Value Stream Mapping (VSM) is one of the basic tools of Lean Methods. Every process has a value stream – whether in production, logistics or office areas (where the Makigami method is used). VSM is available for all areas or departments. With value stream analysis, you record the actual status of process structure, material stocks and information flow – from the supplier to the customer. We analyze it and highlight already existing points of conflict (Kaizen flashes). With the value stream design, you will receive the proposal for a completely new structure with the presentation of improvements in control, organization, lead time and inventory variables.

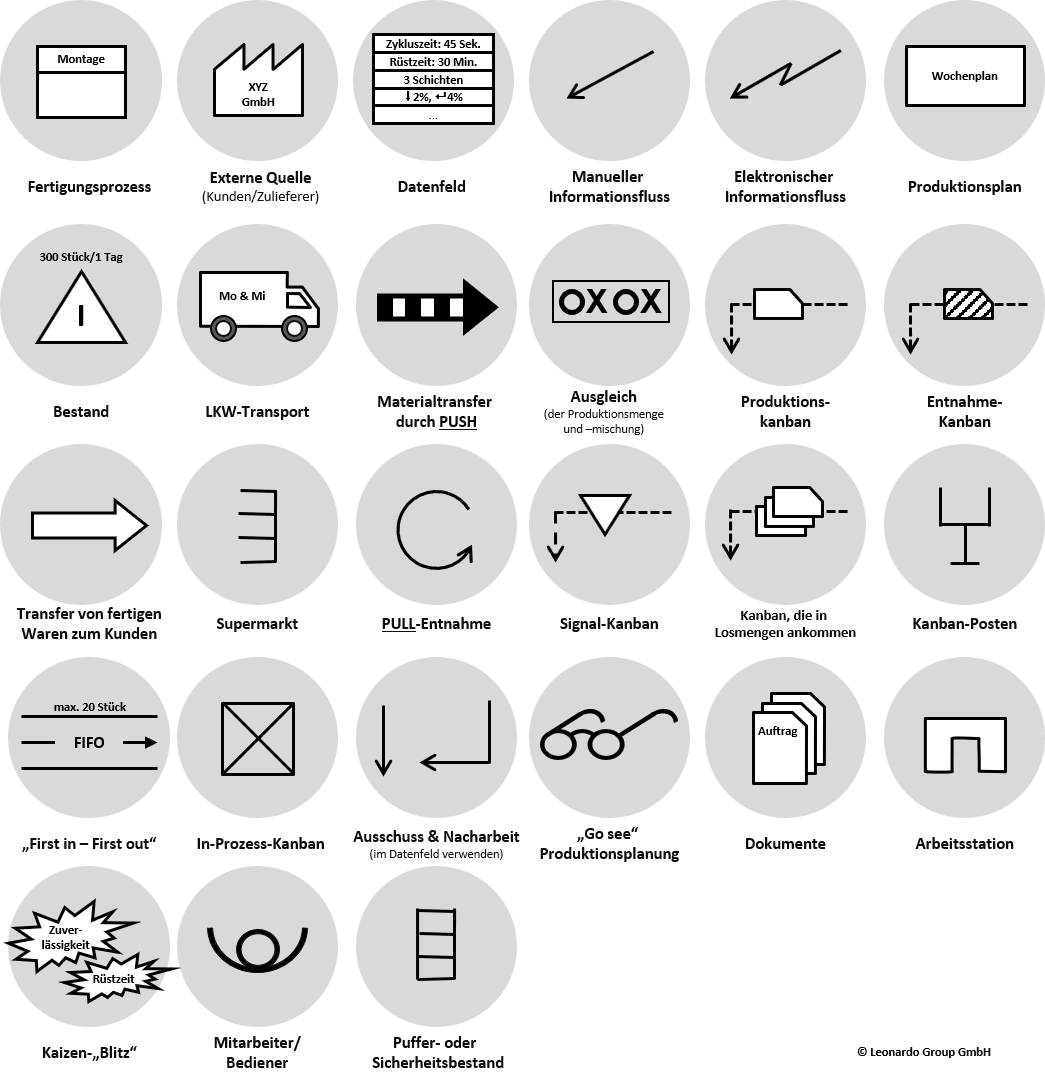

There is uniform symbolism for the visualization of the value stream. Potential waste and process uncertainties become visible on the basis of the visualized process, which are marked with corresponding symbols (Kaizen flashes).

After the value stream analysis (current state), the next step is what is known as the value stream design (future state). You will recognize immediate improvement measures through the marked out “Kaizen flashes” and become aware of the far-reaching to radical changes that are necessary. From this, you will derive strategic decisions and an operational implementation plan.

Use

- Transparency of the actual situation and target scenario

- Potential becomes visible

- Implementation plan, resource plan and time schedule are worked out